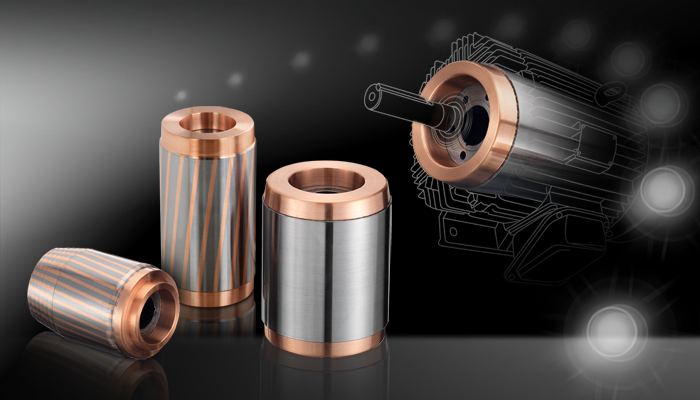

Copper Rotor Die Casting

-

What Is Copper Rotor?

The copper rotor is manufactured from magnetic steel(silicon steel sheet). The aluminum internal guide rod and end collar are replaced by copper.

-

Why You Should Select Copper?

The copper features superior electrical conductivity and hence it is the best material for rotor. The electrical conductivity of copper is 57 ms/m which is much higher than aluminum with 37 ms/m, as such copper has been widely applied in the manufacturing of induction motors in the world.

Benefits of Replacing Aluminum with Copper

High Efficiency

The Superior electrical conductivity of copper may reduce copper loss and temperature growth. With a same volume of motor, the motor with copper rotor exhibits higher efficiency than that with aluminum rotor.

Long Lifespan

When motor running temperature is reduced by 10˚C, its device life can be extended double. The low running temperature of a motor with copper rotor in combination with copper’s high heat dissipation efficiency result in less dissipation parts used on a motor, and therefore higher efficiency can be obtained.

Small Volume and Low Cost

The use of copper rotor may reduce motor volume and weight, however it is able to maintain the original efficiency. This is because the copper rotor may allow the rotor and motor lengths to be shortened, but it still maintain the same performance as that of a motor with aluminum rotor.

Copper rotor Specification:

Terms |

Specification |

||

Applicable motor type |

Copper rotor spindle motor |

Copper rotor induction motor |

Copper rotor fan motor |

Motor efficiency class |

IE4 |

IE4 |

IE4 |

Size |

ø190 x 120mm 150L |

ø160 x 95mm 90L |

ø140 x 75mm 110L |

Number of poles |

4 |

4 |

2 |

Rated Power |

15 kW |

1.5 kW |

2.2 kW |

Frequency |

100~400 Hz |

60 Hz |

60 Hz |

Synchronized speed |

12000 rpm |

1800 rpm |

3600 rpm |

• Specifications and design characteristics are subject to change without prior notice. |

|||

資料建構中

資料建構中

Chia Yow Metals Co., Ltd. 嘉祐鋁業股份有限公司

- TEL: +886-4-2520 4435

- FAX: +886-4-2520 2189

- Email:chiayow@hotmail.com